ws2 powder

-

WS2 Powder

WS2 Powder as a solid lubricant has remarkable characteristics in terms of physical properties. WS2 Powder is most commonly used as a lubricant in petroleum-based oils and greases. Among solid lubricants, the coefficient of friction of WS2 Powder tends to decrease with increasing load. WS2 Powder is also lubricious at high temperatures of 450°C, helping to prevent sintering or seizing. Grease added with WS2 Powder has excellent high temperature resistance, wear resistance, good adhesion, water resistance, oxidation resistance and mechanical stability. After adding WS2 Powder, the working limit high temperature of ultra-high temperature grease reaches 800℃, and the working limit low temperature of low temperature grease reaches -60℃. WS2 Powder is a solid lubricant grade available in two grades- High-purity ultra-fine and High-purity coarse particles.Typical WS2 content (calculated average) is 99.9%.

Email Details -

Hot

WS2

WS2 is widely used in mold release agents, ball and roller bearing lubricants, and engine and driveline components. WS2 can be applied to metal wearing parts and molds to prolong component life and reduce wear. Due to the extremely low coefficient of friction of WS2, it is possible to prevent the carbonization of the parts where the material is processed due to heat. WS2 is widely used in mold release agents, ball and roller bearing lubricants, and engine and driveline components. Also as a lubricant, compared with MoS2, WS2 is artificially synthesized and MoS2 is naturally formed. Compared with the impurity content, the WS2 produced by the synthetic method has high purity and low impurity content. MoS2 is produced from molybdenum concentrate after beneficiation and purification. The purity of molybdenum disulfide is lower than that of WS2. WS2 is a solid lubricant grade available in two grades- High-purity ultra-fine and High-purity coarse particles.Typical WS2 content (calculated average) is 99.9%.

Email Details -

Tungsten Disulfide

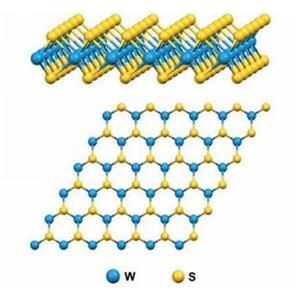

As a solid lubricant, Tungsten Disulfide is suitable for lubrication under high temperature, high pressure, high load and high vacuum conditions. Tungsten Disulfide can be added to engineering plastics to make self-lubricating components. Alternatively, Tungsten Disulfide is mixed with some volatile solvents and sprayed on the metal surface to improve the life of the die and the smoothness of the workpiece in stamping forging. The crystal structure of Tungsten Disulfide is a typical hexagonal crystal layered structure. In the crystal structure of Tungsten Disulfide, each layer is composed of two layers of hexagonal sulfur atoms sandwiched by a layer of metal tungsten atoms, and the sulfur atoms and tungsten atoms form a triangular pyramid. Valence bonds are connected, and the layers are bound by relatively weak van der Waals forces. This connection makes the crystal structure of Tungsten Disulfide strong sliding between the layers, and the sulfur atoms are easily physically or chemically adsorbed with most metals to form a transfer film, and friction mostly occurs between the lubricating film and the transfer film. Therefore, although the friction sheet does not necessarily wear out, the damaged part of the film layer can be repaired by moving the lubricating film on the lubricated material and the WS2 debris accumulated on both sides of the friction part. Tungsten Disulfide is a solid lubricant grade available in two grades- High-purity ultra-fine and High-purity coarse particles.Typical WS2 content (calculated average) is 99.9%.

Email Details -

Tungsten Disulfide Powder

Tungsten Disulfide Powder is widely used. Tungsten Disulfide Powder can be used in equipment running in chemically active medium, carbon industry, aerospace, machinery manufacturing, engineering plastics, petrochemical and so on. Also as a lubricant,Tungsten Disulfide Powder is more wear-resistant than molybdenum disulfide. In air, Tungsten Disulfide Powder acts as a lubricant in the temperature range of -273°C to 450°C. Tungsten Disulfide Powder is inert, inorganic, non-toxic and non-corrosive. Compared with molybdenum disulfide, under air conditions, molybdenum disulfide begins to oxidize at 350 °C, while Tungsten Disulfide Powder begins to oxidize at 425 °C. The oxidation temperature of Tungsten Disulfide Powder is about 100°C higher than that of molybdenum disulfide. Tungsten Disulfide Powder has excellent heat resistance and extreme pressure properties, and Tungsten Disulfide Powder has a lower coefficient of friction. Tungsten Disulfide Powder is a solid lubricant grade available in two grades- High-purity ultra-fine and High-purity coarse particles.Typical WS2 content (calculated average) is 99.9%.

Email Details -

Tungsten Disulfide For Carbon Brush

Tungsten Disulfide For Carbon Brushe is widely used in electric brushes, rubber gaskets, O-rings, satellite and aircraft parts, high vacuum applications, and cryopump seals. Adding 3-5% of Tungsten Disulfide For Carbon Brush to the brush can effectively prolong the life of the brush by 20%-40%; Tungsten Disulfide For Carbon Brush is especially suitable for brushes for power tools and household appliances, and the effect is remarkable.Brushes prepared by adding tungsten disulfide composites. Because Tungsten Disulfide For Carbon Brush has good anti-wear and lubricating properties, Tungsten Disulfide For Carbon Brush can significantly reduce the wear degree of the commutator on the carbon brush, which can prolong the service life of the carbon brush, reduce the operating noise of the motor equipment and improve the equipment. Operational stability. The motor carbon brush prepared by adding Tungsten Disulfide For Carbon Brush composite material can give full play to the lubricity of tungsten disulfide on the surface of the commutator, stabilize the commutation performance, the commutation current will be more stable, and the brush temperature will not change due to the current And the temperature rises suddenly, and then burns out the commutator. Adding 5-10% Tungsten Disulfide For Carbon Brush to the graphite mechanical seal can effectively reduce the wear rate and prolong the life of the seal by more than 30%. Tungsten Disulfide For Carbon Brush is a solid lubricant grade available in two grades- High-purity ultra-fine and High-purity coarse particles.Typical WS2 content (calculated average) is 99.9%.

Email Details