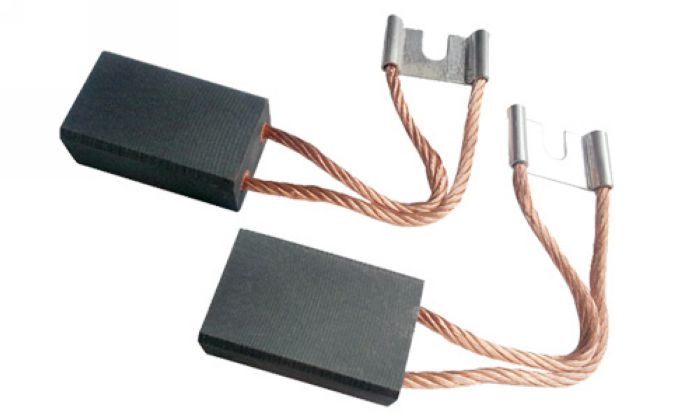

Tungsten Disulfide For Carbon Brushe is widely used in electric brushes, rubber gaskets, O-rings, satellite and aircraft parts, high vacuum applications, and cryopump seals.

Adding 3-5% of Tungsten Disulfide For Carbon Brush to the brush can effectively prolong the life of the brush by 20%-40%; Tungsten Disulfide For Carbon Brush is especially suitable for brushes for power tools and household appliances, and the effect is remarkable.Brushes prepared by adding tungsten disulfide composites. Because Tungsten Disulfide For Carbon Brush has good anti-wear and lubricating properties, Tungsten Disulfide For Carbon Brush can significantly reduce the wear degree of the commutator on the carbon brush, which can prolong the service life of the carbon brush, reduce the operating noise of the motor equipment and improve the equipment. Operational stability. The motor carbon brush prepared by adding Tungsten Disulfide For Carbon Brush composite material can give full play to the lubricity of tungsten disulfide on the surface of the commutator, stabilize the commutation performance, the commutation current will be more stable, and the brush temperature will not change due to the current And the temperature rises suddenly, and then burns out the commutator.

Adding 5-10% Tungsten Disulfide For Carbon Brush to the graphite mechanical seal can effectively reduce the wear rate and prolong the life of the seal by more than 30%.

Tungsten Disulfide For Carbon Brush is a solid lubricant grade available in two grades- High-purity ultra-fine and High-purity coarse particles.Typical WS2 content (calculated average) is 99.9%.

Tungsten Disulfide For Carbon Brush

Introduction

Tungsten Disulfide For Carbon Brushe is widely used in electric brushes, rubber gaskets, O-rings, satellite and aircraft parts, high vacuum applications, and cryopump seals.

Adding 3-5% of Tungsten Disulfide For Carbon Brush to the brush can effectively prolong the life of the brush by 20%-40%; Tungsten Disulfide For Carbon Brush is especially suitable for brushes for power tools and household appliances, and the effect is remarkable.Brushes prepared by adding tungsten disulfide composites. Because Tungsten Disulfide For Carbon Brush has good anti-wear and lubricating properties, Tungsten Disulfide For Carbon Brush can significantly reduce the wear degree of the commutator on the carbon brush, which can prolong the service life of the carbon brush, reduce the operating noise of the motor equipment and improve the equipment. Operational stability. The motor carbon brush prepared by adding Tungsten Disulfide For Carbon Brush composite material can give full play to the lubricity of tungsten disulfide on the surface of the commutator, stabilize the commutation performance, the commutation current will be more stable, and the brush temperature will not change due to the current And the temperature rises suddenly, and then burns out the commutator.

Adding 5-10% Tungsten Disulfide For Carbon Brush to the graphite mechanical seal can effectively reduce the wear rate and prolong the life of the seal by more than 30%.

Tungsten Disulfide For Carbon Brush is a solid lubricant grade available in two grades- High-purity ultra-fine and High-purity coarse particles.Typical WS2 content (calculated average) is 99.9%.

Typical data of Tungsten Disulfide For Carbon Brush:

Specification Writers: These values are not intended for use in preparing specifications. Please contact your local dealer before writing specifications on this product.

Item | Description | |

Appearance | Gray-black powder | |

CHEMICAL SPECIFICATIONS | Inspection Items | Specification |

Composition content(%,≥) | WS2 | ≥99.90 |

W | ≥74.06 | |

(%,≤)Impurity content | Fe | 0.005 0 |

Mo | 0.005 0 | |

Cu | 0.005 0 | |

Pb | 0.003 0 | |

Cd | 0.003 0 | |

Hg | 0.003 0 | |

Si | 0.005 0 | |

O | 0.150 0 | |

H2O | 0.100 0 | |

Particles size specifications by microtrac of Tungsten Disulfide For Carbon Brush:

Grade | High-purity ultra-fine | High-purity coarse particles | |||

Diameter at 50%,μm | 3-4 | 9-10 | 15-18 | 20-24 | 25-28 |

Typical particle size by fisher sub-sizer and bulk density of Tungsten Disulfide For Carbon Brush:

Grade | High-purity ultra-fine | High-purity coarse particles | |||

Fisher number,μm | 0.4-0.7 | 0.8-1.1 | 1.9 | 3.8 | 5.0 |

Packaging of Tungsten Disulfide For Carbon Brush:25Kg/drum

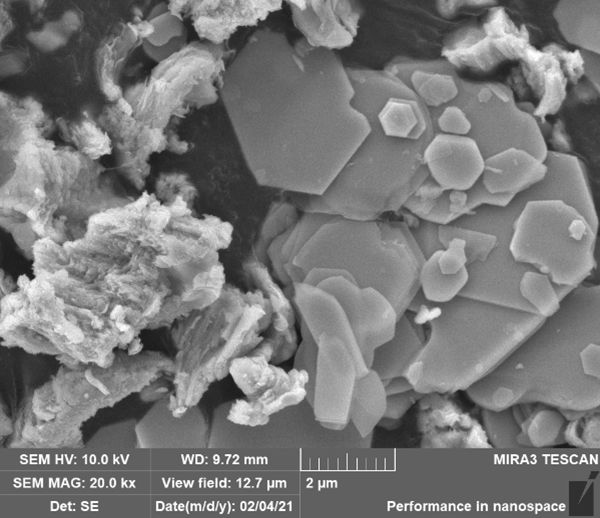

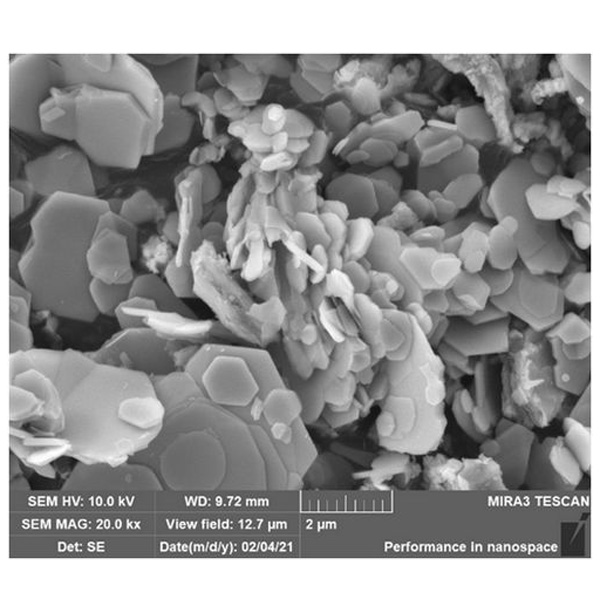

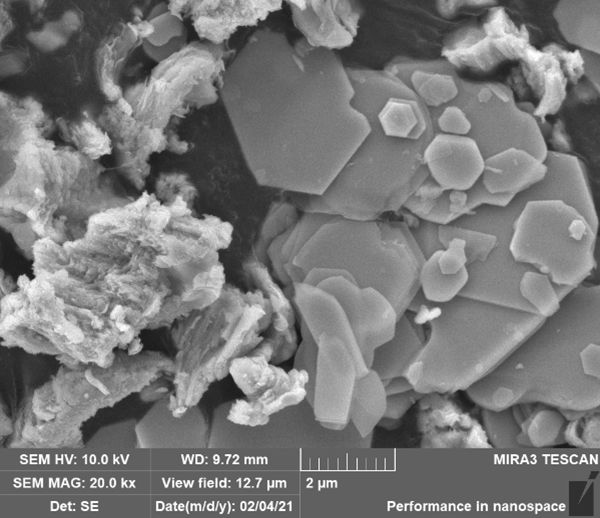

FIG.1 SEM image of Tungsten Disulfide For Carbon Brush

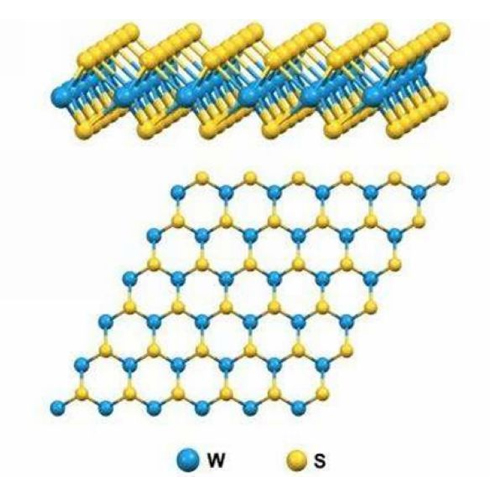

The crystal structure of Tungsten Disulfide For Carbon Brush is a typical hexagonal crystal layered structure.

FIG.2 Packaging of Tungsten Disulfide For Carbon Brush.

On January 30, 2023, molybdenum price rose by more than 20% in a single day, breaking a new 17-year high. Molybdenum is known as the "war metal", "steel warrior". Molybdenum is valued by more and more countries. China is the world's richest country in molybdenum resources, with reserves of 4.3 million tons, followed by the United States (2.7 million tons) and Chile (1.8 million tons), which acco...more