As a solid lubricant, Tungsten Disulfide is suitable for lubrication under high temperature, high pressure, high load and high vacuum conditions. Tungsten Disulfide can be added to engineering plastics to make self-lubricating components. Alternatively, Tungsten Disulfide is mixed with some volatile solvents and sprayed on the metal surface to improve the life of the die and the smoothness of the workpiece in stamping forging.

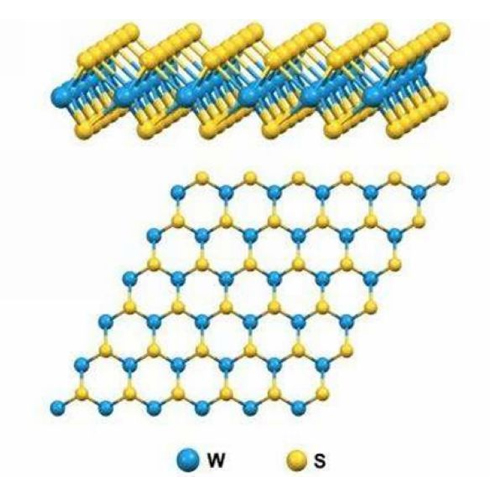

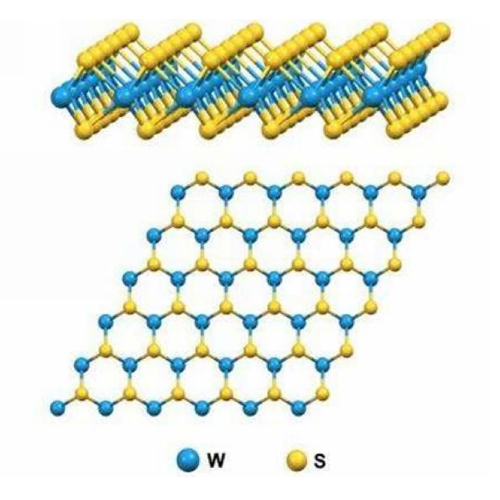

The crystal structure of Tungsten Disulfide is a typical hexagonal crystal layered structure. In the crystal structure of Tungsten Disulfide, each layer is composed of two layers of hexagonal sulfur atoms sandwiched by a layer of metal tungsten atoms, and the sulfur atoms and tungsten atoms form a triangular pyramid. Valence bonds are connected, and the layers are bound by relatively weak van der Waals forces. This connection makes the crystal structure of Tungsten Disulfide strong sliding between the layers, and the sulfur atoms are easily physically or chemically adsorbed with most metals to form a transfer film, and friction mostly occurs between the lubricating film and the transfer film. Therefore, although the friction sheet does not necessarily wear out, the damaged part of the film layer can be repaired by moving the lubricating film on the lubricated material and the WS2 debris accumulated on both sides of the friction part.

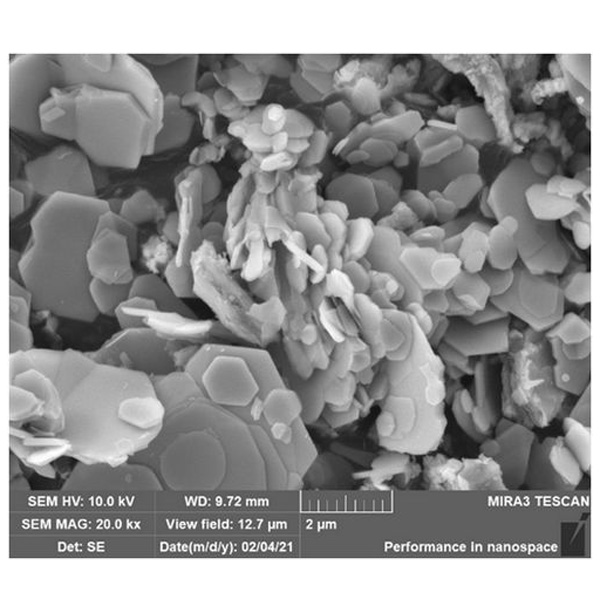

Tungsten Disulfide is a solid lubricant grade available in two grades- High-purity ultra-fine and High-purity coarse particles.Typical WS2 content (calculated average) is 99.9%.

Tungsten Disulfide

Introduction

As a solid lubricant, Tungsten Disulfide is suitable for lubrication under high temperature, high pressure, high load and high vacuum conditions. Tungsten Disulfide can be added to engineering plastics to make self-lubricating components. Alternatively, Tungsten Disulfide is mixed with some volatile solvents and sprayed on the metal surface to improve the life of the die and the smoothness of the workpiece in stamping forging.

The crystal structure of Tungsten Disulfide is a typical hexagonal crystal layered structure. In the crystal structure of Tungsten Disulfide, each layer is composed of two layers of hexagonal sulfur atoms sandwiched by a layer of metal tungsten atoms, and the sulfur atoms and tungsten atoms form a triangular pyramid. Valence bonds are connected, and the layers are bound by relatively weak van der Waals forces. This connection makes the crystal structure of Tungsten Disulfide strong sliding between the layers, and the sulfur atoms are easily physically or chemically adsorbed with most metals to form a transfer film, and friction mostly occurs between the lubricating film and the transfer film. Therefore, although the friction sheet does not necessarily wear out, the damaged part of the film layer can be repaired by moving the lubricating film on the lubricated material and the WS2 debris accumulated on both sides of the friction part.

Tungsten Disulfide is a solid lubricant grade available in two grades- High-purity ultra-fine and High-purity coarse particles.Typical WS2 content (calculated average) is 99.9%.

Typical data of Tungsten Disulfide:

Specification Writers: These values are not intended for use in preparing specifications. Please contact your local dealer before writing specifications on this product.

Item | Description | |

Appearance | Gray-black powder | |

CHEMICAL SPECIFICATIONS | Inspection Items | Specification |

Composition content(%,≥) | WS2 | ≥99.90 |

W | ≥74.06 | |

(%,≤)Impurity content | Fe | 0.005 0 |

Mo | 0.005 0 | |

Cu | 0.005 0 | |

Pb | 0.003 0 | |

Cd | 0.003 0 | |

Hg | 0.003 0 | |

Si | 0.005 0 | |

O | 0.150 0 | |

H2O | 0.100 0 | |

Particles size specifications by microtrac of Tungsten Disulfide:

Grade | High-purity ultra-fine | High-purity coarse particles | |||

Diameter at 50%,μm | 3-4 | 9-10 | 15-18 | 20-24 | 25-28 |

Typical particle size by fisher sub-sizer and bulk density of Tungsten Disulfide:

Grade | High-purity ultra-fine | High-purity coarse particles | |||

Fisher number,μm | 0.4-0.7 | 0.8-1.1 | 1.9 | 3.8 | 5.0 |

Packaging of Tungsten Disulfide:25Kg/drum

FIG.1 Bearings with added tungsten disulfide.

Tungsten disulfide can be used in bearings. Because tungsten disulfide has good corrosion resistance, when tungsten disulfide is coated on the metal surface of deep groove ball bearings, tungsten disulfide can provide maximum corrosion protection for the component, thereby effectively reducing surface corrosion. In addition, tungsten disulfide also has good high temperature resistance and extreme pressure resistance, making the bearing suitable for the working environment of deep groove ball bearings with heavy loads.

FIG.2 Packaging of Tungsten Disulfide.

On January 30, 2023, molybdenum price rose by more than 20% in a single day, breaking a new 17-year high. Molybdenum is known as the "war metal", "steel warrior". Molybdenum is valued by more and more countries. China is the world's richest country in molybdenum resources, with reserves of 4.3 million tons, followed by the United States (2.7 million tons) and Chile (1.8 million tons), which acco...more