WS2 is widely used in mold release agents, ball and roller bearing lubricants, and engine and driveline components. WS2 can be applied to metal wearing parts and molds to prolong component life and reduce wear. Due to the extremely low coefficient of friction of WS2, it is possible to prevent the carbonization of the parts where the material is processed due to heat.

WS2 is widely used in mold release agents, ball and roller bearing lubricants, and engine and driveline components.

Also as a lubricant, compared with MoS2, WS2 is artificially synthesized and MoS2 is naturally formed. Compared with the impurity content, the WS2 produced by the synthetic method has high purity and low impurity content. MoS2 is produced from molybdenum concentrate after beneficiation and purification. The purity of molybdenum disulfide is lower than that of WS2.

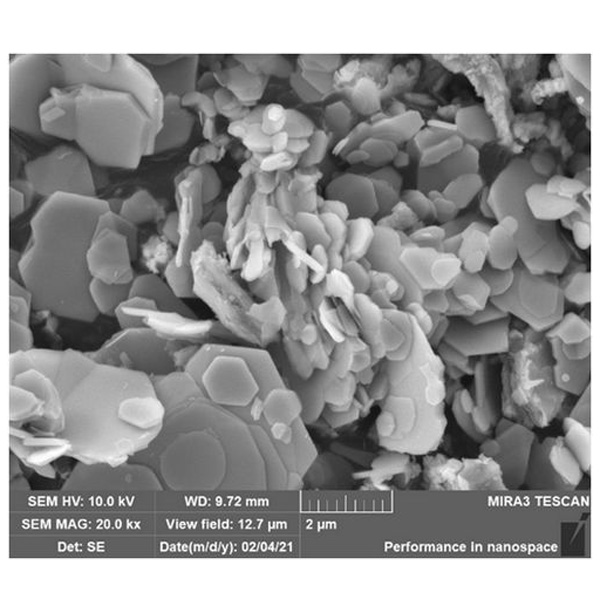

WS2 is a solid lubricant grade available in two grades- High-purity ultra-fine and High-purity coarse particles.Typical WS2 content (calculated average) is 99.9%.

WS2

Introduction

WS2 is widely used in mold release agents, ball and roller bearing lubricants, and engine and driveline components. WS2 can be applied to metal wearing parts and molds to prolong component life and reduce wear. Due to the extremely low coefficient of friction of WS2, it is possible to prevent the carbonization of the parts where the material is processed due to heat.

WS2 is widely used in mold release agents, ball and roller bearing lubricants, and engine and driveline components.

Also as a lubricant, compared with MoS2, WS2 is artificially synthesized and MoS2 is naturally formed. Compared with the impurity content, the WS2 produced by the synthetic method has high purity and low impurity content. MoS2 is produced from molybdenum concentrate after beneficiation and purification. The purity of molybdenum disulfide is lower than that of WS2.

WS2 is a solid lubricant grade available in two grades- High-purity ultra-fine and High-purity coarse particles.Typical WS2 content (calculated average) is 99.9%.

Typical data of WS2:

Specification Writers: These values are not intended for use in preparing specifications. Please contact your local dealer before writing specifications on this product.

Item | Description | |

Appearance | Gray-black powder | |

CHEMICAL SPECIFICATIONS | Inspection Items | Specification |

Composition content(%,≥) | WS2 | ≥99.90 |

W | ≥74.06 | |

(%,≤)Impurity content | Fe | 0.005 0 |

Mo | 0.005 0 | |

Cu | 0.005 0 | |

Pb | 0.003 0 | |

Cd | 0.003 0 | |

Hg | 0.003 0 | |

Si | 0.005 0 | |

O | 0.150 0 | |

H2O | 0.100 0 | |

Particles size specifications by microtrac of WS2:

Grade | High-purity ultra-fine | High-purity coarse particles | |||

Diameter at 50%,μm | 3-4 | 9-10 | 15-18 | 20-24 | 25-28 |

Typical particle size by fisher sub-sizer and bulk density of WS2:

Grade | High-purity ultra-fine | High-purity coarse particles | |||

Fisher number,μm | 0.4-0.7 | 0.8-1.1 | 1.9 | 3.8 | 5.0 |

Packaging of WS2:25Kg/drum

FIG.1 Packaging of WS2.

WS2 is packed in fiber drums, 25 kg per drum.

FIG.2 Mold for cream bottle treated with WS2.

After surface treatment with WS2, mold scratches are reduced and mold release is easier.

On January 30, 2023, molybdenum price rose by more than 20% in a single day, breaking a new 17-year high. Molybdenum is known as the "war metal", "steel warrior". Molybdenum is valued by more and more countries. China is the world's richest country in molybdenum resources, with reserves of 4.3 million tons, followed by the United States (2.7 million tons) and Chile (1.8 million tons), which acco...more