Tungsten Disulfide Powder is widely used. Tungsten Disulfide Powder can be used in equipment running in chemically active medium, carbon industry, aerospace, machinery manufacturing, engineering plastics, petrochemical and so on.

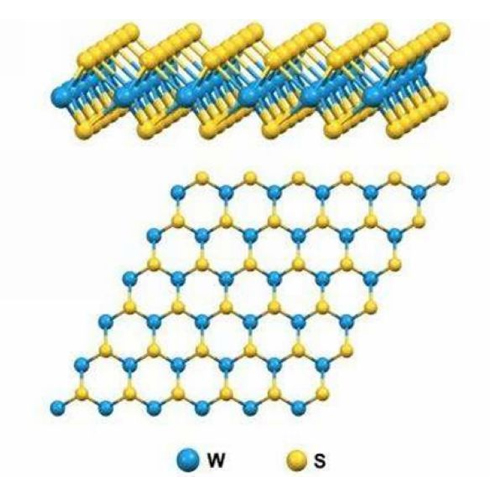

Also as a lubricant,Tungsten Disulfide Powder is more wear-resistant than molybdenum disulfide. In air, Tungsten Disulfide Powder acts as a lubricant in the temperature range of -273°C to 450°C. Tungsten Disulfide Powder is inert, inorganic, non-toxic and non-corrosive.

Compared with molybdenum disulfide, under air conditions, molybdenum disulfide begins to oxidize at 350 °C, while Tungsten Disulfide Powder begins to oxidize at 425 °C. The oxidation temperature of Tungsten Disulfide Powder is about 100°C higher than that of molybdenum disulfide. Tungsten Disulfide Powder has excellent heat resistance and extreme pressure properties, and Tungsten Disulfide Powder has a lower coefficient of friction.

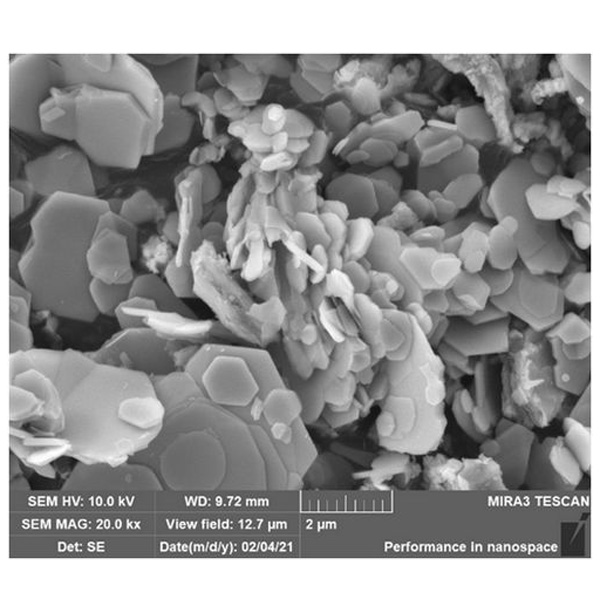

Tungsten Disulfide Powder is a solid lubricant grade available in two grades- High-purity ultra-fine and High-purity coarse particles.Typical WS2 content (calculated average) is 99.9%.

Tungsten Disulfide Powder

Introduction

Tungsten Disulfide Powder is widely used. Tungsten Disulfide Powder can be used in equipment running in chemically active medium, carbon industry, aerospace, machinery manufacturing, engineering plastics, petrochemical and so on.

Also as a lubricant,Tungsten Disulfide Powder is more wear-resistant than molybdenum disulfide. In air, Tungsten Disulfide Powder acts as a lubricant in the temperature range of -273°C to 450°C. Tungsten Disulfide Powder is inert, inorganic, non-toxic and non-corrosive.

Compared with molybdenum disulfide, under air conditions, molybdenum disulfide begins to oxidize at 350 °C, while Tungsten Disulfide Powder begins to oxidize at 425 °C. The oxidation temperature of Tungsten Disulfide Powder is about 100°C higher than that of molybdenum disulfide. Tungsten Disulfide Powder has excellent heat resistance and extreme pressure properties, and Tungsten Disulfide Powder has a lower coefficient of friction.

Tungsten Disulfide Powder is a solid lubricant grade available in two grades- High-purity ultra-fine and High-purity coarse particles.Typical WS2 content (calculated average) is 99.9%.

Typical data of Tungsten Disulfide Powder:

Specification Writers: These values are not intended for use in preparing specifications. Please contact your local dealer before writing specifications on this product.

Item | Description | |

Appearance | Gray-black powder | |

CHEMICAL SPECIFICATIONS | Inspection Items | Specification |

Composition content(%,≥) | WS2 | ≥99.90 |

W | ≥74.06 | |

(%,≤)Impurity content | Fe | 0.005 0 |

Mo | 0.005 0 | |

Cu | 0.005 0 | |

Pb | 0.003 0 | |

Cd | 0.003 0 | |

Hg | 0.003 0 | |

Si | 0.005 0 | |

O | 0.150 0 | |

H2O | 0.100 0 | |

Particles size specifications by microtrac of Tungsten Disulfide Powder:

Grade | High-purity ultra-fine | High-purity coarse particles | |||

Diameter at 50%,μm | 3-4 | 9-10 | 15-18 | 20-24 | 25-28 |

Typical particle size by fisher sub-sizer and bulk density of Tungsten Disulfide Powder:

Grade | High-purity ultra-fine | High-purity coarse particles | |||

Fisher number,μm | 0.4-0.7 | 0.8-1.1 | 1.9 | 3.8 | 5.0 |

Packaging of Tungsten Disulfide Powder:25Kg/drum

FIG.1 Car lights treated with Tungsten Disulfide Powder.

In the production process of the lamp, if the lamp core-pulling slider is lubricated with lubricating oil, there will be oil pollution, which makes it difficult to electroplating in the post-processing of the product, and the rejection rate is as high as 60%. And if the headlight core pulling slider is not refueled, it is very easy to be bitten to death. Now use Tungsten Disulfide Powder to deal with the core-pulling slider of the headlight, and no need to add lubricating oil after treatment. The product has no oil pollution, and the product scrap rate is reduced from 60% to less than 10%, which greatly reduces the production cost. At the same time, due to the use of Tungsten Disulfide Powder to reduce the friction coefficient in the production process, the problems of wear and seizure are solved.

FIG.2 Packaging of Tungsten Disulfide Powder.

On January 30, 2023, molybdenum price rose by more than 20% in a single day, breaking a new 17-year high. Molybdenum is known as the "war metal", "steel warrior". Molybdenum is valued by more and more countries. China is the world's richest country in molybdenum resources, with reserves of 4.3 million tons, followed by the United States (2.7 million tons) and Chile (1.8 million tons), which acco...more