molybdenum

-

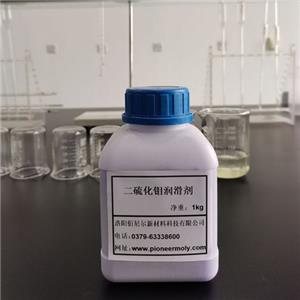

Molybdenum Disulfide Lubricating Paste

Molybdenum Disulfide Lubricating Paste is a quick-drying lubricant. Molybdenum Disulfide Lubricating Paste is also known as Molybdenum Disulfide Lubrication , Molybdenum Disulfide Lubricant ,and Molybdenum Disulfide Quick-drying Lubricant. Molybdenum Disulfide Lubricating Paste can provide long-lasting lubrication for sliding surfaces with light load or slowly moving to heavy load. Molybdenum Disulfide Lubricating Paste can be used for sliding parts with an operating temperature range of up to 350°C, including rollers, flat bearings, gears, sliding systems, cams and valves. Tips on how to use Molybdenum Disulfide Lubricating Paste:Shake the tank before use to mix the liquid in the tank evenly. For best results, please wipe clean the parts to be sprayed. Use a brush to evenly coat the surface of the part, and the coating thickness is recommended to be no more than 0.5mm.

Molybdenum Disulfide Lubricating Paste Molybdenum Disulfide Lubrication Molybdenum Disulfide Lubricant Molybdenum Disulfide Quick-drying LubricantEmail Details -

Molybdenum Trioxide Smoke Suppressant

Molybdenum Trioxide Smoke Suppressant is an additive flame retardant with dual functions of flame retardancy and smoke suppression. Compounding with other flame retardants can reduce cost, improve flame retardancy of Molybdenum Trioxide Smoke Suppressant and reduce smoke. Molybdenum Trioxide Smoke Suppressant also has the dual effects of flame retardant and smoke suppression. Molybdenum Trioxide Smoke Suppressant shows a certain synergistic effect with aluminum hydroxide trihydrate and antimony oxide. Molybdenum Trioxide Smoke Suppressant is more effective for chlorine-containing adhesives. The reference dosage of 0.5 to 5.0 parts of Molybdenum Trioxide Smoke Suppressant can reduce the amount of smoke produced by 30% to 80%, and increase the oxygen index by 10% to 20%. Typical elemental analysis of Molybdenum Trioxide Smoke Suppressant products is shown in Table 1. Typical MoO3 content (calculated average) is 99.9%.

Molybdenum Trioxide Smoke Suppressant High purity molybdenum trioxide Molybdenum Trioxide Powder Molybdenum TrioxideEmail Details -

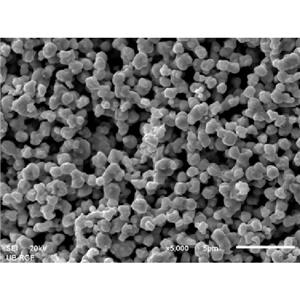

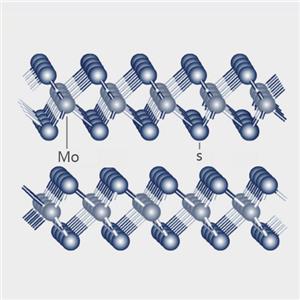

Molybdenum Disulfide Superfine Grade

Compared with molybdenum disulfide technical grade and Molybdenum disulfide technical fine grade, Molybdenum Disulfide Superfine Grade has incomparable advantages in industrial applications. Molybdenum disulfide itself has good lubricating properties. However, Molybdenum Disulfide Superfine Grade has high temperature, low temperature, high load, high speed, chemical corrosion and modern ultra-high temperature. Under vacuum conditions, Molybdenum Disulfide Superfine Grade has more excellent lubricity for equipment. Molybdenum Disulfide Superfine Grade is a good solid lubricant that can be lubricated in a vacuum or air environment for a long time. The friction coefficient is relatively low, and Molybdenum Disulfide Superfine Grade can be lubricated for a long time in the air below 350 ℃. With more than ten years of research and development/ R&D experience, we can provide an annual output of 1,000 tons of Molybdenum Disulfide Superfine Grade as a patented technology product.

Molybdenum disulfide superfine grade MoS2 technical grade Molybdenum disulfide technical fine grade Molybdenum DisulfideEmail Details -

Molybdenum Disulfide For Wiper

Molybdenum Disulfide For Wiper is added to the wiper body in the form of powder, which can be used for high-power generators and starter generators. The actual service life is 600 hours. Molybdenum Disulfide For Wiper is also successfully used in the main generator of helicopters with a service life of more than 500 hours. With more than ten years of R&D experience, we can provide an annual output of 1,000 tons of Molybdenum Disulfide For Wiper as a patented technology product. Molybdenum Disulfide For Wiper is a lubricant grade of molybdenum disulfide (MoS2) available in two grades-Technical Fechnical Fine,and Super Fine.Typical MoS2 content (calculated average) is 98.5%.

Email Details -

Molybdenum Disulfide For Plastics

Molybdenum Disulfide For Plastics is added to plastics to make modified plastics containing molybdenum disulfide powder, which can improve its bearing capacity and wear resistance without affecting the impact resistance and fatigue resistance of unmodified plastics such as cast nylon , widely used to manufacture gears, bearings, star wheels and sleeves, can widely replace wear-resistant parts of mechanical equipment, replace copper and alloys as wear-resistant and wearing parts of equipment, such as bushings, bearing bushes, bushings, lining plates, Gears, worm rollers, copper guide rails, piston rings, sealing rings, sliders, ball bowls, impellers, vanes, cams, nuts, valve plates, pipes, stuffing boxes, racks, pulleys, pump rotors, etc. Molybdenum Disulfide For Plastics is a good solid lubricant that can be lubricated in a vacuum or air environment for a long time. The friction coefficient is relatively low, and Molybdenum Disulfide For Plastics can be lubricated for a long time in the air below 350 ℃. With more than ten years of R&D experience, we can provide an annual output of 1,000 tons of Molybdenum Disulfide For Plastics as a patented technology product. Molybdenum Disulfide For Plastics is a lubricant grade of molybdenum disulfide (MoS2) available in three grades-Technical, Technical Fechnical Fine,and Super Fine.Typical MoS2 content (calculated average) is 98.5%.

Molybdenum Disulfide For Plastics Molybdenum Disulfide For Nylon Modification Molybdenum Disulfide For PA66 PA66 Molybdenum DisulfideEmail Details -

Molybdenum Disulfide For Carbon Brush

Molybdenum Disulfide For Carbon Brush is an energy-saving material. Various metal materials and alloy materials added with Molybdenum Disulfide For Carbon Brush after surface treatment have significantly prolonged service life, and also play a huge role in mechanical lubrication. With more than ten years of research and development/ R&D experience, it can provide an annual output of 1,000 tons of Molybdenum Disulfide For Carbon Brush as a patented technology product. Molybdenum Disulfide For Carbon Brush is a lubricant grade of molybdenum disulfide (MoS2) available in two grades-Technical Fechnical Fine,and Super Fine.Typical MoS2 content (calculated average) is 98.5%.

Email Details