molybdenum

-

Hot

Molybdenum Disulfide Powder

Molybdenum Disulfide Powder can be directly used as a solid lubricant. Molybdenum Disulfide Powder also mainly applies to produce solid lubricant grease, lubricant additives, friction improver and molybdenum metallic compounds. Molybdenum Disulfide Powder is a lubricant grade of molybdenum disulfide (MoS2) available in three grades-Technical, Technical Fechnical Fine,and Super Fine.Typical MoS2 content (calculated average) is 98.5%. Molybdenum Disulfide Powder is a good solid lubricant that can be lubricated in a vacuum or air environment for a long time. The friction coefficient is relatively low, and Molybdenum Disulfide Powder can be lubricated for a long time in the air below 350 ℃. With more than ten years of research and development experience, it can provide an annual output of 1,000 tons of Molybdenum Disulfide Powder as a patented technology product.

Email Details -

Hot

Solid Molybdenum alkylthiocarbamate (MoDTC)

Solid Molybdenum alkylthiocarbamate (MoDTC) is a organic Molybdenum compound. It can work as a Friction Modifer, EP/Antiwear agent and Antioxidant in lubricating greases. Have the advantages of including Higher Molybdenum content, low phosphorus content, Excellent friction-reducing property and Good EP/AW and antioxidation performance.

Solid Molybdenum alkylthiocarbamate (MoDTC) Molybdenum alkylthiocarbamate (MoDTC) PNR1002A Friction Modifier/MoDTCEmail Details -

Hot

Molybdenum Disulfide Technical Grade

The S in Molybdenum Disulfide Technical Grade has strong adhesion to the metal, so that Molybdenum Disulfide Technical Grade can well adhere to the metal surface and always play a lubricating function, especially Molybdenum Disulfide Technical Grade still has a low friction factor under high temperature and high vacuum conditions. Molybdenum Disulfide Technical Grade is a good solid lubricant that can be lubricated in a vacuum or air environment for a long time. The friction coefficient is relatively low, and Molybdenum Disulfide Technical Grade can be lubricated for a long time in the air below 350 ℃. With more than ten years of research and development experience, it can provide an annual output of 550 tons ofMolybdenum Disulfide Technical Gradeas a patented technology product. Molybdenum Disulfide Technical Grade is a lubricant grade of molybdenum disulfide (MoS2). Typical MoS2 content (calculated average) is 98.5%.

Email Details -

Hot

Molybdenum Trioxide

Molybdenum Trioxide is a raw material for preparing metal molybdenum and molybdenum compounds available in three grades - MoO3-1, MoO3-2 and MoO3-3. Typical MoO3 content (calculated average) is 99.9%. Molybdenum Trioxide is widely used as a catalyst in the petroleum industry. Molybdenum Trioxide can also be used for enamel, pigment and medicine. Molybdenum Trioxide has a certain synergistic effect with aluminum hydroxide trihydrate and antimony oxide.

Molybdenum trioxide Molybdenum trioxide powder High Purity Molybdenum Trioxide Molybdenum Trioxide Smoke SuppressantEmail Details -

Hot

Molybdenum Powder

Molybdenum Powder is a non renewable scarce strategic resource. The application of Molybdenum Powder has developed rapidly. At present, Molybdenum Powder has been widely used in powder metallurgy, molybdenum target, heater, high-temperature structural parts, etc. Molybdenum Powder is also widely used in metallurgy, aerospace, petrochemical, machinery manufacturing, high-temperature kiln and other industries. Molybdenum Powder is divided into two specifications according to different purity,FMo-01 and FMo-02.

Email Details -

Spherical Molybdenum Powder

Spherical molybdenum powder is produced by using molybdenum powder or molybdenum wire as raw material by laser, plasma and other processes. Spherical molybdenum powder has the advantage of good fluidity and is mainly used in the spraying industry, near-net shaping of molybdenum precision devices and metal 3D printing. product is gray black powder.

Email Details -

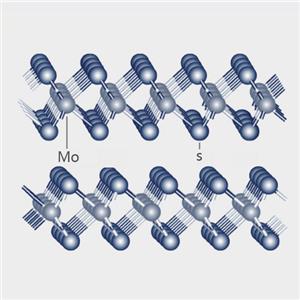

Molybdenum Disulfide For Release Agent

Molybdenum Disulfide For Release Agent is used as a powder system as a mold release agent, which has the advantages of high temperature resistance, wear resistance and tensile strength. In Molybdenum Disulfide For Release Agent a layer of molybdenum atoms is sandwiched between two layers of sulfur atoms. When Molybdenum Disulfide For Release Agent is dispersed between two metal surfaces, molybdenum disulfide binds to each metal surface through sulfur atoms, which hinders the contact of asperities (irregular parts of the metal surface), and sliding contact is in the sulfur atoms between the outer layers, the interaction between them is very weak. Therefore, the surfaces that bind Molybdenum Disulfide For Release Agent can easily slide against each other. The friction coefficient is relatively low, and Molybdenum Disulfide For Release Agent can be lubricated for a long time in the air below 350 ℃.

Email Details -

Molybdenum Disulfide For Brake Pad

Molybdenum Disulfide For Brake Pad is added to brake pads as a friction reducing material. As a friction reducing material, Molybdenum Disulfide For Brake Pad has very good dispersion, wear resistance and noise reduction effect. When the friction temperature increases sharply, molybdenum trioxide will appear during the oxidation of Molybdenum Disulfide For Brake Pad, and it will expand with the increase of temperature, thereby increasing the friction. The specific gravity of Molybdenum Disulfide For Brake Pad crystals is 4.5-5.2. As the fineness of Molybdenum Disulfide For Brake Pad increases, the specific surface area also increases, the specific gravity decreases, and the weight of the brake pads also decreases to a certain extent. The use of Molybdenum Disulfide For Brake Pad can effectively improve the wear resistance and stability of brake pad products.

Email Details -

Molybdenum Disulfide For Valve Guide

Molybdenum Disulfide For Valve Guide can be used as a dry lubricant in dispersions.Various metal materials and alloy materials added with Molybdenum Disulfide For Valve Guide after surface treatment have significantly prolonged service life, and also play a huge role in mechanical lubrication. Molybdenum Disulfide For Valve Guide is a good solid lubricant that can be lubricated in a vacuum or air environment for a long time. The friction coefficient is relatively low, and Molybdenum Disulfide For Valve Guide can be lubricated for a long time in the air below 350 ℃. With more than ten years of research and development experience, it can provide an annual output of 1,000 tons of Molybdenum Disulfide For Valve Guide as a patented technology product. Molybdenum Disulfide For Valve Guide is a lubricant grade of molybdenum disulfide (MoS2) available in three grades-Technical, Technical Fechnical Fine,and Super Fine.Typical MoS2 content (calculated average) is 98.5%.

Email Details