Molybdenum Disulfide Lubricating Paste is a quick-drying lubricant. Molybdenum Disulfide Lubricating Paste is also known as Molybdenum Disulfide Lubrication , Molybdenum Disulfide Lubricant ,and Molybdenum Disulfide Quick-drying Lubricant. Molybdenum Disulfide Lubricating Paste can provide long-lasting lubrication for sliding surfaces with light load or slowly moving to heavy load. Molybdenum Disulfide Lubricating Paste can be used for sliding parts with an operating temperature range of up to 350°C, including rollers, flat bearings, gears, sliding systems, cams and valves.

Tips on how to use Molybdenum Disulfide Lubricating Paste:Shake the tank before use to mix the liquid in the tank evenly. For best results, please wipe clean the parts to be sprayed. Use a brush to evenly coat the surface of the part, and the coating thickness is recommended to be no more than 0.5mm.

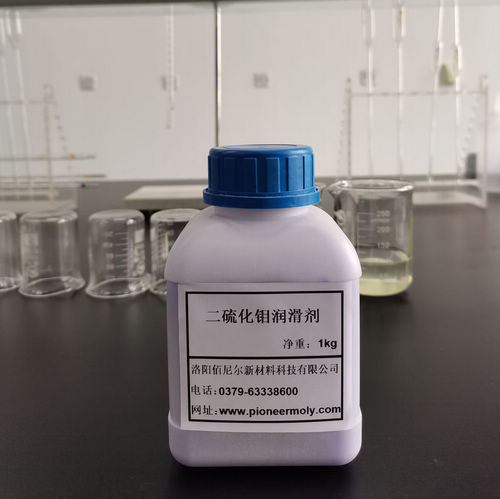

Molybdenum Disulfide Lubricating Paste

Introduction

A quick-drying lubricant

Molybdenum Disulfide Lubricating Paste is a quick-drying lubricant. Molybdenum Disulfide Lubricating Paste is also known as Molybdenum Disulfide Lubrication , Molybdenum Disulfide Lubricant ,and Molybdenum Disulfide Quick-drying Lubricant. Molybdenum Disulfide Lubricating Paste can provide long-lasting lubrication for sliding surfaces with light load or slowly moving to heavy load. Molybdenum Disulfide Lubricating Paste can be used for sliding parts with an operating temperature range of up to 350°C, including rollers, flat bearings, gears, sliding systems, cams and valves.

Tips on how to use Molybdenum Disulfide Lubricating Paste:Shake the tank before use to mix the liquid in the tank evenly. For best results, please wipe clean the parts to be sprayed. Use a brush to evenly coat the surface of the part, and the coating thickness is recommended to be no more than 0.5mm.

Applications of Molybdenum Disulfide Lubricating Paste:

l Provide long-lasting lubrication for sliding surfaces with light load or slowly moving to heavy load

l Used for sliding parts with an operating temperature range of up to 350°C, including rollers, flat bearings, gears, sliding systems, cams and valves

Main performance of Molybdenum Disulfide Lubricating Paste:

l Prevent machine parts from corroding/seizing, abrasion and scratching

l Resistant to contamination by dust, dirt and other pollutants

l It can also be compatible with other lubricants after use

l Avoid tight corrosion / seizure of precision threaded parts

l Strong adhesion, excellent anti-rust effect

Typical data of Molybdenum Disulfide Lubricating Paste:

Specification Writers: These values are not intended for use in preparing specifications. Please contact your local dealer before writing specifications on this product.

Item | Description |

Analysis | |

solid content | 40-50 % by wt (GB/T1725) |

Appearance | dark gray film, Uniform, smooth and defect-free |

film adhesion | Level 1 (GB/T1720) |

Film flexibility | 1mm (GB/T1731) |

Film impact resistance | 50cm (GB/T1732) |

Heat resistance 260℃×3h /Low temperature resistance -55℃×3h | No film blistering, film peeling and film cracking, with acceptable adhesion (HB 6688) |

Resistant to liquid medium 24℃×24h | No film softening, film blistering and film exfoliation, with acceptable adhesion (HB 6688) |

Film friction coefficient | 0.12 max |

Physical Properties | |

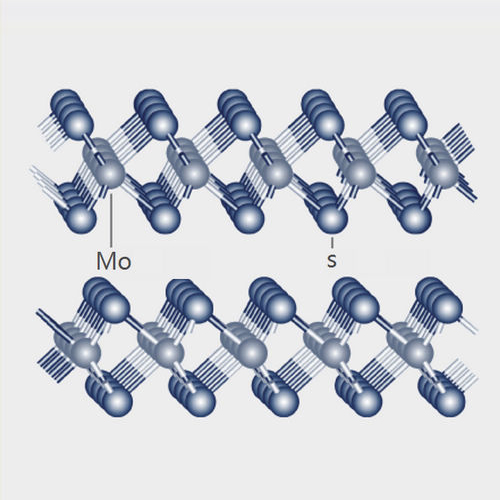

Solid lubricating materials | molybdenum disulfide,RTV resin |

Chemical solvent | solvent oil, petroleum sodium sulfonate |

Surface drying time | 15 minutes (room temperature) |

Completely dry (20℃) | 2 hours |

Temperature | |

Operating temperature | 5°C to 40°C (room temperature recommended) |

Working temperature range | -40℃ to +350℃ (forming thin film) |

Usable Life and Storage | |

Storage | store below 40℃, avoid direct sunlight |

usable Life | 24 months |

Packaging Details | 1kg/can |

Instructions | |

Shake the tank before use to mix the liquid in the tank evenly. For best results, please wipe clean the parts to be sprayed. Use a brush to evenly coat the surface of the part, and the coating thickness is recommended to be no more than 0.5mm. | |

FIG.1 Demonstration: How to use Molybdenum Disulfide Lubricating Paste to coat a swatch.

Using a brush, dip Molybdenum Disulfide Lubricating Paste, apply an even layer, and dry quickly to form a lubricating coating.

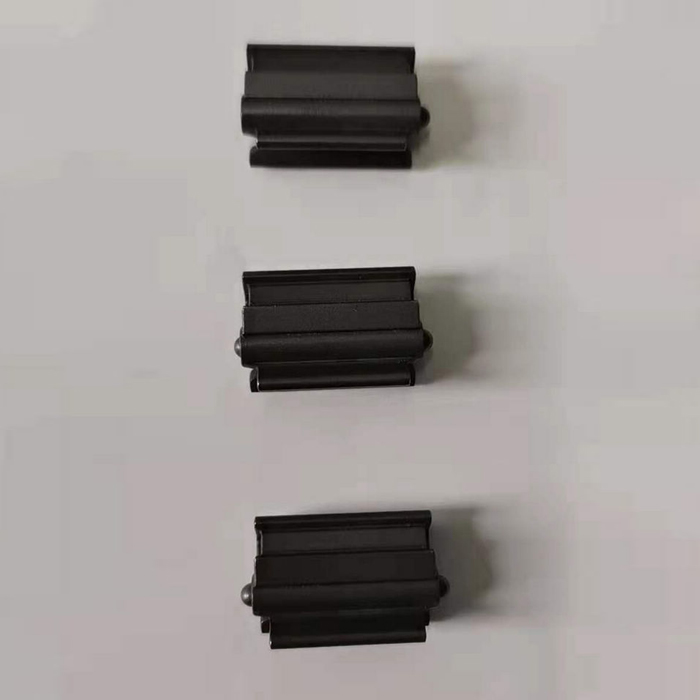

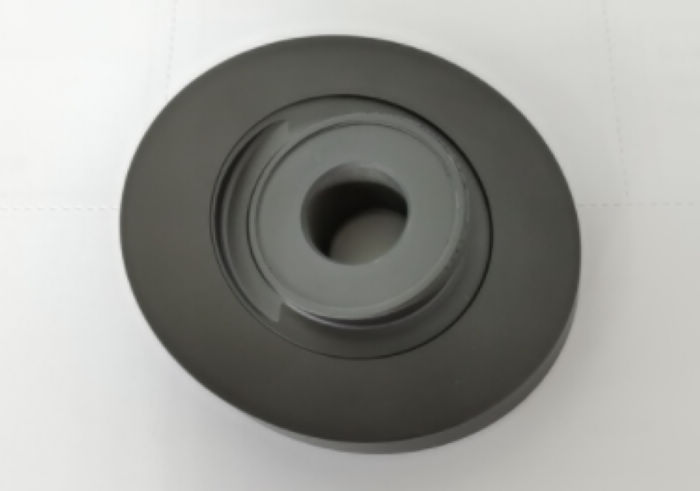

FIG.2 Workpiece (surface sprayed with Molybdenum Disulfide Lubricating Paste)

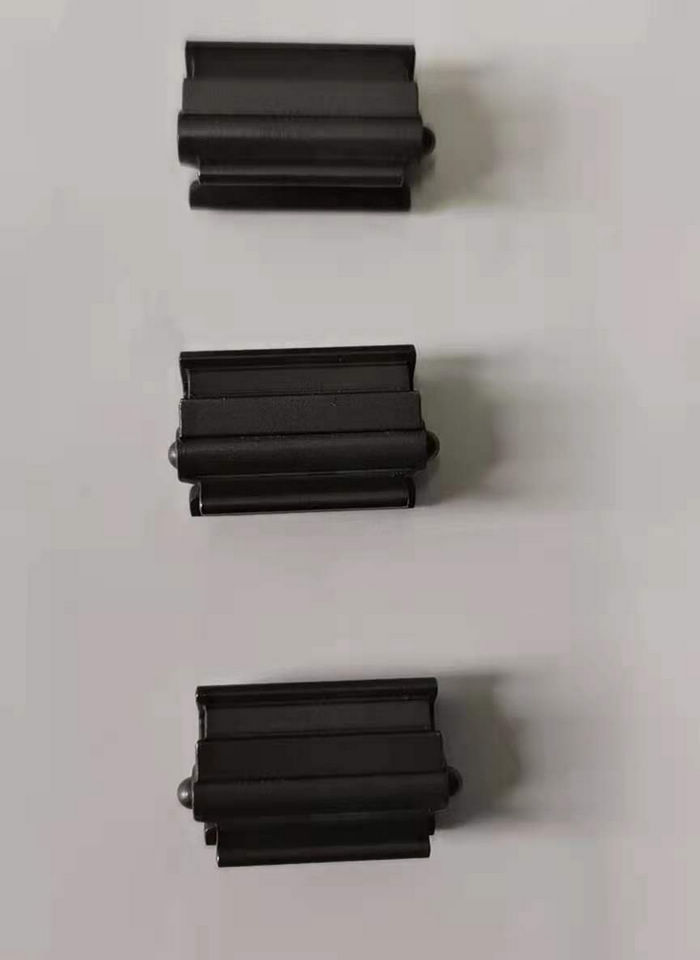

FIG.3 Refrigerator compressor accessories with Molybdenum Disulfide Lubricating Paste

FIG.4 Magnesium alloy auto parts Molybdenum Disulfide Lubricating Paste coating

FIG.5 Iron/Aluminum swash plate with Molybdenum Disulfide Lubricating Paste coating

FIG.6 Molybdenum Disulfide Lubricating Paste coating for automotive electronic seat accessories

On January 30, 2023, molybdenum price rose by more than 20% in a single day, breaking a new 17-year high. Molybdenum is known as the "war metal", "steel warrior". Molybdenum is valued by more and more countries. China is the world's richest country in molybdenum resources, with reserves of 4.3 million tons, followed by the United States (2.7 million tons) and Chile (1.8 million tons), which acco...more