Tungsten Disulfide Lubricant can be used to prepare special catalytic materials.Tungsten Disulfide Lubricant is mainly used as petroleum catalyst, dry film lubricant.Tungsten Disulfide Lubricant is an additive for high-performance lubricating grease, and can also be used as a battery, semiconductor material, etc. Tungsten Disulfide Lubricant can also be used as an effective catalyst for new inorganic functional materials. Under the condition of isolating the air, the ammonium tetrathiotungstate is heated and decomposed. During heating, the temperature is increased from room temperature to 700-1200°C with a temperature gradient of 100-200°C/hour, and kept at this temperature for 24-48 hours. Then, the temperature is lowered to room temperature with a temperature gradient of 30-110° C./hour, and the material is discharged and pulverized to obtain Tungsten Disulfide Lubricant.

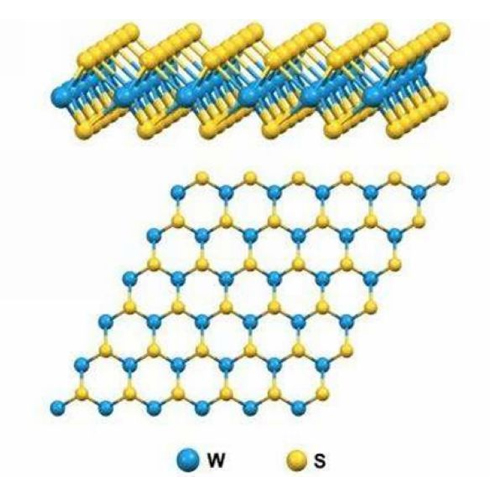

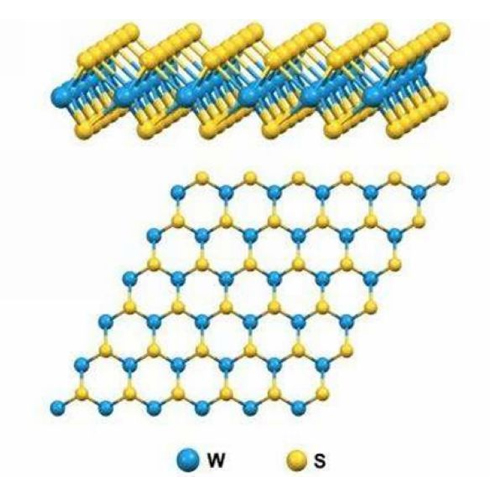

We can produce stable quality, high-purity and ultra-fine Tungsten Disulfide Lubricant with a hexagonal crystal structure.

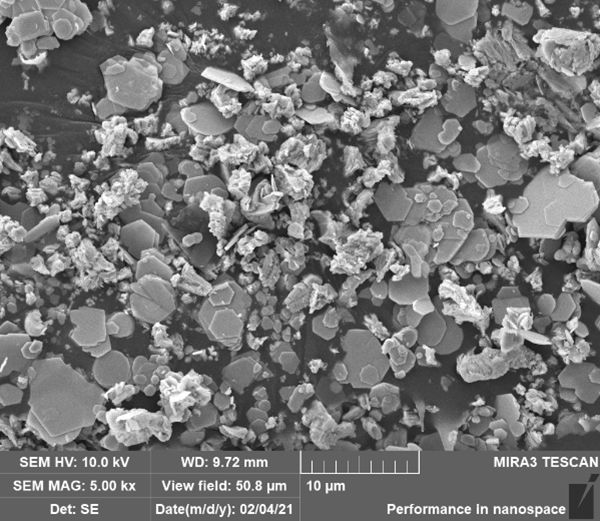

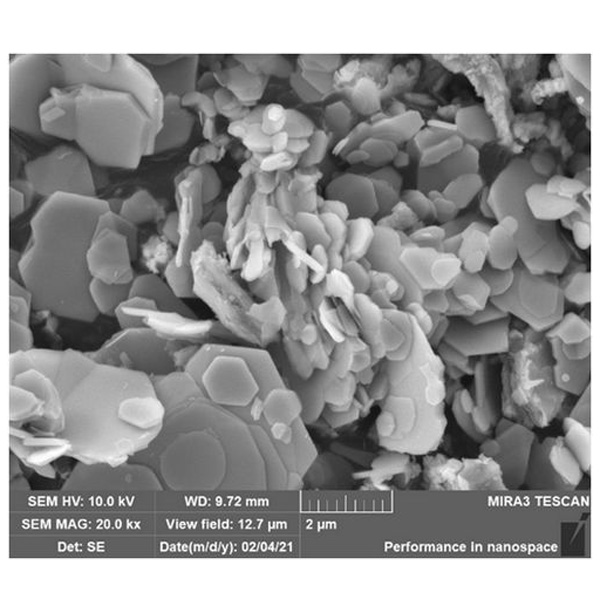

Typical WS2 content is more than 99.9%. Typical W content is 73.5-74.3wt%. Typical particle size :the average scanning electron microscope is 80nm, the interval is 60-120nm.

The packaging of Tungsten Disulfide Lubricant adopts the inner double vacuum packaging and the outer metal barrel, 25 kg per barrel. Tungsten Disulfide Lubricant can also be produced and packaged according to the user's requirements.

Tungsten Disulfide Lubricant

Introduction

A solid lubricant or lubricant additive

Tungsten Disulfide Lubricant can be used to prepare special catalytic materials.Tungsten Disulfide Lubricant is mainly used as petroleum catalyst, dry film lubricant.Tungsten Disulfide Lubricant is an additive for high-performance lubricating grease, and can also be used as a battery, semiconductor material, etc. Tungsten Disulfide Lubricant can also be used as an effective catalyst for new inorganic functional materials. Under the condition of isolating the air, the ammonium tetrathiotungstate is heated and decomposed. During heating, the temperature is increased from room temperature to 700-1200°C with a temperature gradient of 100-200°C/hour, and kept at this temperature for 24-48 hours. Then, the temperature is lowered to room temperature with a temperature gradient of 30-110° C./hour, and the material is discharged and pulverized to obtain Tungsten Disulfide Lubricant.

We can produce stable quality, high-purity and ultra-fine Tungsten Disulfide Lubricant with a hexagonal crystal structure.

Typical WS2 content is more than 99.9%. Typical W content is 73.5-74.3wt%. Typical particle size :the average scanning electron microscope is 80nm, the interval is 60-120nm.

The packaging of Tungsten Disulfide Lubricant adopts the inner double vacuum packaging and the outer metal barrel, 25 kg per barrel. Tungsten Disulfide Lubricant can also be produced and packaged according to the user's requirements.

Applications:

New bulletproof material

High performance anti-wear and anti-friction extreme pressure lubricant

Efficient catalyst

Lubricants of the filling material

The Tungsten Disulfide Lubricant product is divided into two specifications according to different purposes, NW-01 and NW-02.

Specifications of Tungsten Disulfide Lubricant:

Specifications | PARTICLE SIZE,nm | WS2 (%) | surface area(m2/g) | Electron morphology | Appearance |

NW-01 | 50-100 | ≥99.9 | 10.5064 | flaky | black |

NW-02 | ≤100 | ≥99.9 | 21.5289 | spherical | black |

Typical Specifications of Tungsten Disulfide Lubricant:

Formula | Purity(%) | SEM | Crystal Form | Color |

WS2 | 99.9 | 50-200nm | Powder | Grey-black |

FIG.1 The crystal structure of Tungsten Disulfide Lubricant.

The crystal structure of Tungsten Disulfide Lubricant is a typical hexagonal crystal layered structure.

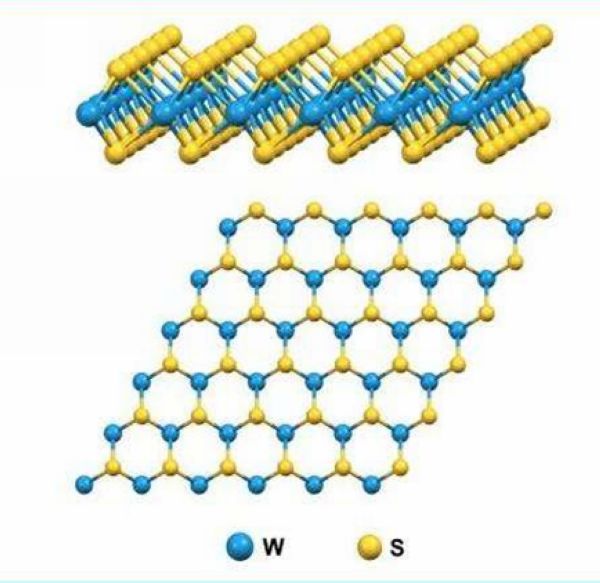

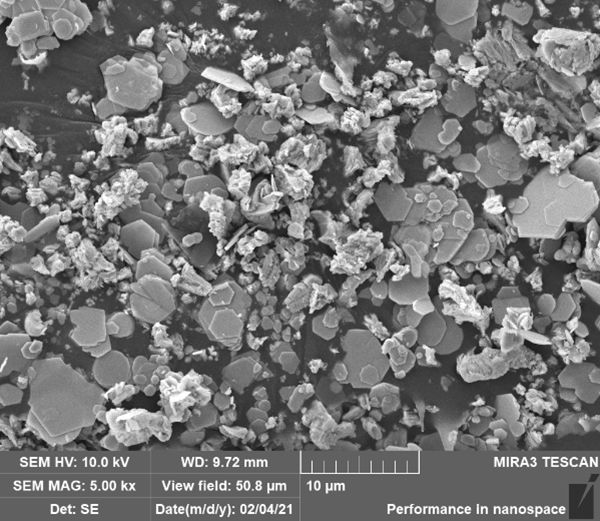

FIG.2 SEM image of Tungsten Disulfide For Carbon Brush

The crystal structure of Tungsten Disulfide For Carbon Brush is a typical hexagonal crystal layered structure.

FIG.3 Nano WS2 are packed in iron drum.

On January 30, 2023, molybdenum price rose by more than 20% in a single day, breaking a new 17-year high. Molybdenum is known as the "war metal", "steel warrior". Molybdenum is valued by more and more countries. China is the world's richest country in molybdenum resources, with reserves of 4.3 million tons, followed by the United States (2.7 million tons) and Chile (1.8 million tons), which acco...more