nano ws2

-

Nano WS2

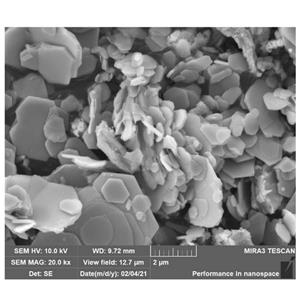

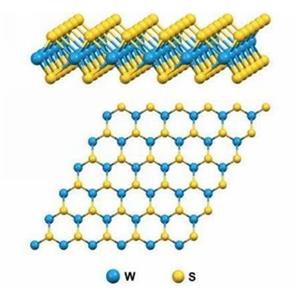

Nano WS2 is used as a lubricant with low friction coefficient and high compressive strength, and is widely used in solid lubrication in aerospace, aviation, military and other fields. The adhesion and coverage of Nano WS2 on the surface of the friction pair are significantly improved, and the anti-wear and anti-wear performance is doubled compared to ordinary WS2. Using ammonium tetrathiotungstate as raw material, WS2 can be obtained by thermal decomposition. The process equipment is simple, does not pollute the environment, and the operation is safe and reliable. It can produce stable quality, high-purity and ultra-fine Nano WS2 with a hexagonal crystal structure. Typical WS2 content is more than 99.9%. Typical W content is 73.5-74.3wt%. Typical particle size :the average scanning electron microscope is 80nm, the interval is 60-120nm.

Email Details -

Nano Tungsten Disulfide

As a solid lubricant ,Nano Tungsten Disulfide is widely used in air vibrators, air motor electrical connectors, circuit breakers and switches (super electrical contact material additive). Compared with conventional tungsten disulfide, Nano Tungsten Disulfide has larger specific surface area, stronger adsorption capacity, higher reactivity and stronger catalytic performance. The production of Nano Tungsten Disulfide is prepared by heating and decomposing ammonium tetrathiotungstate under the condition of isolating air from ammonium tetrathiotungstate. Typical WS2 content is more than 99.9%. Typical W content is 73.5-74.3wt%. Typical particle size :the average scanning electron microscope is 80nm, the interval is 60-120nm.

Email Details -

Tungsten Disulfide Lubricant

Tungsten Disulfide Lubricant can be used to prepare special catalytic materials.Tungsten Disulfide Lubricant is mainly used as petroleum catalyst, dry film lubricant.Tungsten Disulfide Lubricant is an additive for high-performance lubricating grease, and can also be used as a battery, semiconductor material, etc. Tungsten Disulfide Lubricant can also be used as an effective catalyst for new inorganic functional materials. Under the condition of isolating the air, the ammonium tetrathiotungstate is heated and decomposed. During heating, the temperature is increased from room temperature to 700-1200°C with a temperature gradient of 100-200°C/hour, and kept at this temperature for 24-48 hours. Then, the temperature is lowered to room temperature with a temperature gradient of 30-110° C./hour, and the material is discharged and pulverized to obtain Tungsten Disulfide Lubricant. We can produce stable quality, high-purity and ultra-fine Tungsten Disulfide Lubricant with a hexagonal crystal structure. Typical WS2 content is more than 99.9%. Typical W content is 73.5-74.3wt%. Typical particle size :the average scanning electron microscope is 80nm, the interval is 60-120nm. The packaging of Tungsten Disulfide Lubricant adopts the inner double vacuum packaging and the outer metal barrel, 25 kg per barrel. Tungsten Disulfide Lubricant can also be produced and packaged according to the user's requirements.

Email Details