boron nitride powder

-

Hex Boron Nitride

Hex Boron Nitride( HBN) is chemically stable and has the advantages of non-toxicity, chemical stability, corrosion resistance, oxidation resistance, low humidity, biological stability and non-stick properties.Hex Boron Nitride does not react with general metals, rare earth metals, precious metals, semiconductor materials, glass, molten salts, inorganic acids, and alkalis. For most metal melts, such as steel, stainless steel, Al, Fe, Ge, Cu, Ni, Zn, etc., Hex Boron Nitride neither wets nor acts. Hex Boron Nitride is widely used as high temperature thermocouple protective sleeve, melting metal crucibles, utensils, pipelines for conveying liquid metal, pump parts, cast steel molds and high temperature electrical insulating materials. Hex Boron Nitride is insoluble in cold water, and hydrolyzes very slowly when water is boiled and produces a small amount of boric acid and ammonia gas. Hex Boron Nitride does not react with weak acids and strong bases at room temperature. Potassium oxide can be decomposed. The Boron Nitride is divided into two specifications according to different grades, HBN-01 and HBN-02.The chemical composition of the product should meet the requirements in table 3 (mass fraction).

Email Details -

Hot

Hexagonal Boron Nitride Powder

Hexagonal Boron Nitride Powder (HBN) is a covalently bonded crystal composed of nitrogen atoms and boron atoms. Hexagonal Boron Nitride Powder has a layered structure similar to graphite and is a white powder that is loose, lubricated, easy to absorb moisture, and light in weight. Also known as "white graphite". Hexagonal Boron Nitride Powder is a soft material with a Mohs hardness of only 2. Due to the graphite-like layered structure of BN crystals, the dense HBN porcelain body formed by hot pressing of flake crystals has a certain degree of orientation, and this microstructure makes some properties of HBN products have obvious anisotropic characteristics. The mechanical properties of hot-pressed HBN are stronger parallel to the compression direction than perpendicular to the compression direction. Hexagonal Boron Nitride Powder has excellent thermodynamic properties. Hexagonal Boron Nitride Powder has the advantages of high thermal conductivity, high heat capacity, low thermal expansion, thermal shock resistance, high temperature lubricity and high temperature stability.

Email Details -

Boron Nitride For Cosmetics

Boron Nitride For Cosmetics is widely used as an additive in make-up cosmetics, which is moist and has a good pearlescent effect. Boron Nitride For Cosmetics has the advantages of non-abrasion, low wear, dimensional safety, good lubricity, fire resistance and easy processing. The coefficient of friction of Boron Nitride For Cosmetics is as low as 0.16. The friction coefficient of Boron Nitride For Cosmetics does not increase at high temperature, and boron nitride has higher temperature resistance than molybdenum disulfide and graphite. Boron Nitride For Cosmetics can be used up to 900℃ in oxidizing atmosphere and 2000℃ in vacuum. Boron Nitride For Cosmetics has poor lubricating properties at room temperature, so it is often mixed with graphite fluoride, graphite and molybdenum disulfide as a high-temperature lubricant. The Boron Nitride For Cosmetics is divided into two specifications according to different grades, BNR-01 and BNR-02.The chemical composition of the product should meet the requirements in the following table (mass fraction).

Email Details -

Boron Nitride

Boron Nitride products are synthesized from boric acid and melamine at high temperature. Boron Nitride has the advantages of less impurities, high purity, good crystallinity, and adjustable particle size. For different industries, Boron Nitride is mainly divided into: boron nitride for ceramics, Boron Nitride for thermal conductivity, Boron Nitride for cosmetics and Boron Nitride for lubrication. Boron Nitride is used as polymer additives such as functional plastics, epoxy resins, silica gels, polyimides, polyurethanes, nylons, etc. The main function of Boron Nitride is to enhance thermal conductivity, insulation, friction resistance, corrosion resistance, and reduce dielectric constant and dielectric loss. The Boron Nitride is divided into two specifications according to different grades, BNR-01 and BNR-02.The chemical composition of the product should meet the requirements in the following table (mass fraction).

Email Details -

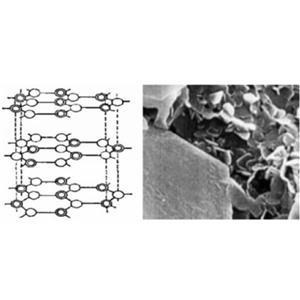

Boron Nitride Carbon

Boron Nitride Carbon (BNC) is a composite product of boron nitride (BN) and boron carbide (B, C). Boron Nitride Carbon has a hexagonal lattice with boron nitride (h-BN) as the parent phase. Among various fine ceramic materials, boron nitride, boron carbide, or other boride ceramics are the most interesting high temperature materials. On this basis, Boron Nitride Carbon, which is composed of boron nitride and boron carbide, is also a new type of fine ceramic material, which has better thermal, chemical, and electrical insulation properties. Existing research: Two-dimensional Boron Nitride Carbon hybrid materials with honeycomb atomic arrangement are a new class of valleytronic materials with tunable energy gaps extending from ultraviolet to visible, near-infrared and far-infrared bands. Experiments have confirmed the existence of valley polarization in this system.

Email Details -

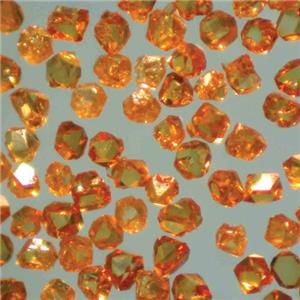

Cubic Boron Nitride Powder

Cubic Boron Nitride Powder is synthesized from hexagonal boron nitride and a catalyst at high temperature and pressure. Cubic Boron Nitride Powder is another new product after the advent of synthetic diamond. Cubic boron nitride has high hardness, thermal stability and chemical inertness, as well as excellent infrared transmittance and wide band gap. The hardness of Cubic Boron Nitride Powder is second only to diamond, but the thermal stability of cubic boron nitride is much higher than that of diamond, and it has greater chemical stability to iron-based metal elements. The grinding performance of the abrasive tool prepared by Cubic Boron Nitride Powder is very good, not only can it be competent for the processing of difficult-to-grind materials, improve the productivity, but also effectively improve the grinding quality of the workpiece.

Email Details -

Cubic Boron Nitride

Cubic Boron Nitride(CBN) is a superhard material whose hardness is second only to diamond and much higher than other materials. Cubic Boron Nitride is widely used in sawing tools, grinding tools, drilling tools and cutting tools. Diamond is easy to be oxidized at high temperature, especially with good affinity with iron-based elements, so it is not suitable for iron-based element ferrous metal processing. Cubic Boron Nitride has good chemical stability, especially compared with diamond, and does not chemically react with iron group elements at temperatures as high as 1100-1300 °C, so it is especially suitable for processing ferrous metal materials.

Email Details