Ammonium Heptamolybdate, also known as ammonium paramolybdate, has high water solubility. Ammonium Heptamolybdate is an important intermediate product in the molybdenum metallurgy process due to its high purity, intact crystal form, smooth surface, large and uniform particle size, which is beneficial to deep processing. Ammonium Heptamolybdate is an important raw material for the production of high-purity molybdenum trioxide, molybdenum powder, doped molybdenum powder and other molybdenum products, as well as various molybdenum processing materials (such as photovoltaic power sources, electronic materials, nuclear energy materials, aerospace materials, etc.) precursor.

The production process methods of Ammonium Heptamolybdate mainly include: evaporative cooling crystallization method, acid precipitation method and combined method.

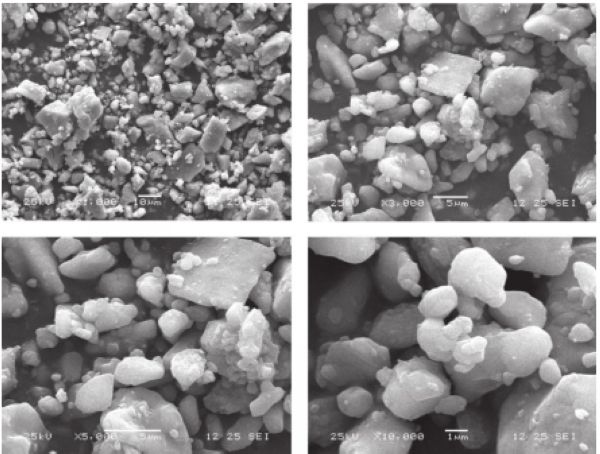

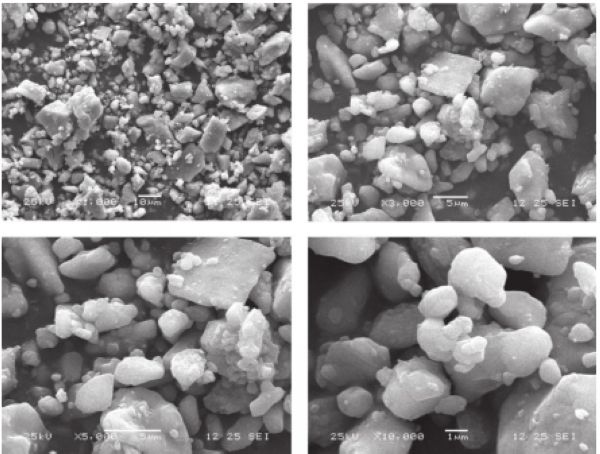

The particles of Ammonium Heptamolybdate are in the form of flakes, and the products have no agglomeration, the surface morphology is complete and smooth, and the particle size is relatively uniform.

Molybdenum content of Ammonium Heptamolybdate is not less than 54.35%.

Ammonium Heptamolybdate

Introduction

Ammonium Heptamolybdate, also known as ammonium paramolybdate, has high water solubility. Ammonium Heptamolybdate is an important intermediate product in the molybdenum metallurgy process due to its high purity, intact crystal form, smooth surface, large and uniform particle size, which is beneficial to deep processing. Ammonium Heptamolybdate is an important raw material for the production of high-purity molybdenum trioxide, molybdenum powder, doped molybdenum powder and other molybdenum products, as well as various molybdenum processing materials (such as photovoltaic power sources, electronic materials, nuclear energy materials, aerospace materials, etc.) precursor. Ammonium Heptamolybdate is widely used in the production of petrochemical catalysts, especially acrylonitrile catalysts, coal liquefaction catalysts, etc., and also in the production of molybdenum carbide, molybdenum nitride precursors, ceramic glazes, pigments and trace fertilizers.

The production process methods of Ammonium Heptamolybdate mainly include: evaporative cooling crystallization method, acid precipitation method and combined method.

1. Chemical and enterprise identification:

Ammonium Heptamolybdate

2. Appearance: according to the particle size, the product is white crystal without visual inclusions.

3. Specifications of Ammonium Heptamolybdate:

the product is divided into four specifications according to different purposes, MSA-0, MSA-1, MSA-2 and MSA-3.

5. Chemical composition of Ammonium Heptamolybdate:

Product brand | MSA-0 | MSA-1 | MSA-2 | MSA-3 | |

Molybdenum content (not less than) | 54.35±0.4 | ||||

Impurity content: (no more than) | K | 0.0060 | 0.0100 | 0.0150 | 0.0180 |

Na | 0.0005 | 0.0008 | 0.0010 | 0.0015 | |

Fe | 0.0005 | 0.0005 | 0.0006 | 0.0010 | |

Al | 0.0005 | 0.0005 | 0.0006 | 0.0008 | |

Si | 0.0005 | 0.0005 | 0.0005 | 0.0010 | |

Sn | 0.0005 | 0.0005 | 0.0005 | 0.0010 | |

Pb | 0.0003 | 0.0005 | 0.0005 | 0.0005 | |

P | 0.0005 | 0.0005 | 0.0005 | 0.0010 | |

Mg | 0.0003 | 0.0005 | 0.0006 | 0.0010 | |

Ca | 0.0005 | 0.0006 | 0.0010 | 0.0015 | |

Cd | 0.0005 | 0.0005 | 0.0005 | 0.0006 | |

Sb | 0.0005 | 0.0005 | 0.0005 | 0.0006 | |

Bi | 0.0005 | 0.0005 | 0.0005 | 0.0006 | |

Cu | 0.0003 | 0.0004 | 0.0005 | 0.0005 | |

Ni | 0.0003 | 0.0003 | 0.0003 | 0.0005 | |

Mn | 0.0003 | 0.0003 | 0.0003 | 0.0005 | |

Cr | 0.0002 | 0.0002 | 0.0007 | 0.0007 | |

W | 0.0100 | 0.0120 | 0.0150 | - | |

Ti | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

As | 0.0005 | 0.0005 | 0.0005 | 0.0005 | |

6.Packaging of Ammonium Heptamolybdate:

The product is packaged in double-layered barrels or bags, and the inner packaging is made of polyethylene plastic film bags with a thickness of not less than 0.05mm and 25kg plastic bags. The mouth of the packaging drum should be sealed with lead. The net weight of each barrel is 25kg.

FIG.1 SEM images of Ammonium Heptamolybdate at different magnifications.

The particles of Ammonium Heptamolybdate are in the form of flakes, and the products have no agglomeration, the surface morphology is complete and smooth, and the particle size is relatively uniform.

FIG.2 Finished Ammonium Heptamolybdate to be shipped.

On January 30, 2023, molybdenum price rose by more than 20% in a single day, breaking a new 17-year high. Molybdenum is known as the "war metal", "steel warrior". Molybdenum is valued by more and more countries. China is the world's richest country in molybdenum resources, with reserves of 4.3 million tons, followed by the United States (2.7 million tons) and Chile (1.8 million tons), which acco...more