Visited to a professional tribology testing technology institute

We always firmly believe in corporate responsibility, deep cultivation of professional fields and excellence in development. At the end of 2022, from the point of view of customers to meet the needs of customers, with technical problems encountered in the process of market development, the molybdenum disulfide sales team of Pioneer New Material Technology Co., Ltd. went to Jinan, Shandong Province, to visit Jinan Yihua Tribology Testing Institute.

FIG.1 Second laboratory of Jinan Yihua Tribology Testing Institute

Our team visited all kinds of friction and wear testing machines and related equipment and instruments in the laboratory of the tribology testing Institute, to understand and exchange the test ideas of different material fields and different testing purposes and the main functions and principles of each equipment, and carried out a one-day field test of eight groups of molybdenum disulfide sample materials on the universal friction and wear testing machine. The team obtained the first hand tribological test data to guide customers to select molybdenum disulfide products. During sample testing, the team had in-depth discussions with experts and scholars of the institute on tribology issues related to powder metallurgy and lubricating coating, and exchanged and learned from each other,and display molybdenum disulfide, molybdenum trioxide and sodium molybdate products. This visit, benefit a lot!

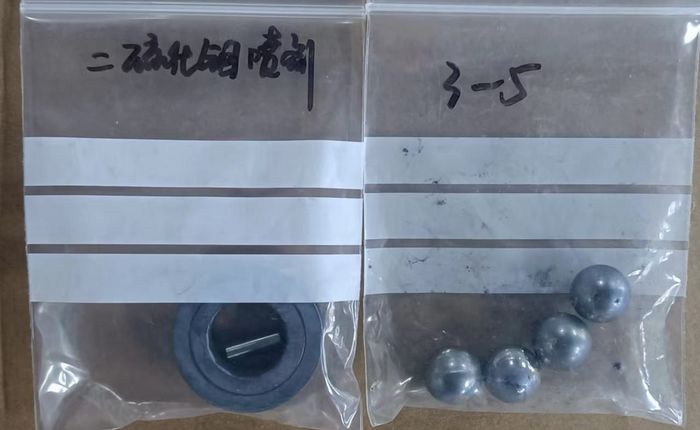

FIG.2 Coupling pin ring and four balls used for tribological testing of molybdenum disulfide

Jinan Yihua Tribology Testing Research Institute is an open professional research institution. The tribology testing laboratory was established in 2013 to serve the tribology testing needs of various industries and fields. In 2022, the total number of tests conducted by the institute is nearly 1,500, a third more than that in 2021. According to industry statistics, 50% are conducted by universities, 23% by enterprises, 15% by third-party testing institutions, and 12% by scientific research institutes. According to the statistics of the material field, the proportion of metal alloy is 65.03% at most, with an increase of 67% compared with 2021, coating coating 21% and lubricating oil 4%.